DIY / inset sewing machine table

inset sewing machine table

As an improvisor I really enjoy rigging up my sewing space and equipment to suit my particular needs.

Here is how I inset my Juki TL-98E home sewing machine into a table and lined it with old rotary cutting mats. Be sure to pay attention to the features of your machine and adapt these general guidelines accordingly.

Materials and Tools:

Drill

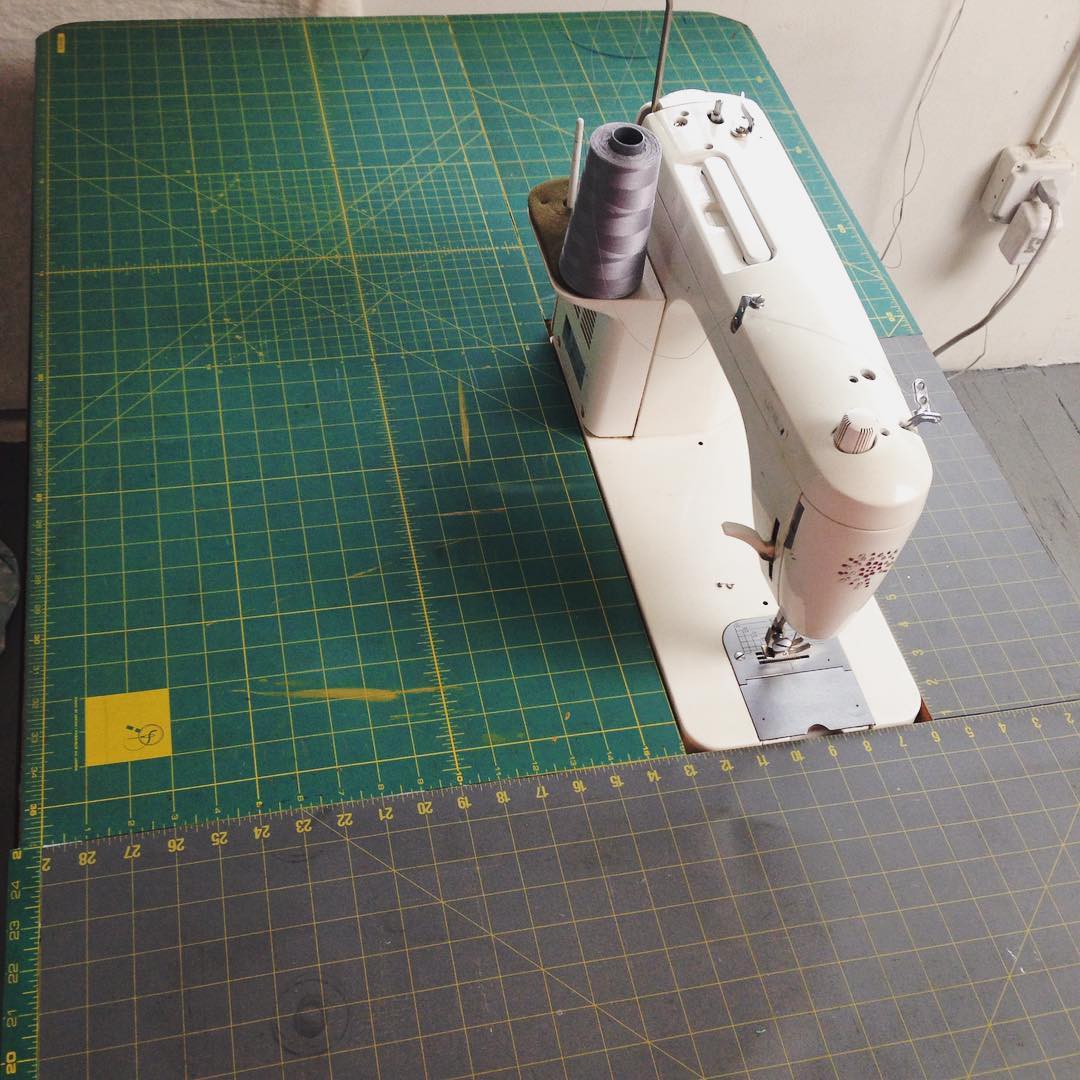

underside-view-of-my-diy-sewing-machine-table-as-requested-makingdo-sewingtools-figuringitout_24364710919_o

How to:

Position your machine on top of a 6'foot pressboard folding table at a distance that is comfortable for you to work at but also allows room for the knee lift to clear the metal edge of the table underneath (if you have a Juki or a machine with a knee lift), and then use a sharpie to mark around the footprint of the machine. I placed my machine approximately 6" from the edge.

Drill a hole inside the footprint large enough to slip in the tip of a handsaw or jigsaw, and then saw around the marked footprint.

Saw out a small curve on the back end of the sewing machine placement, to allow the cords to rise up through the table and plug into the machine. Since I could access the bobbin case without difficulty on my Juki, it wasn't necessary to saw out any other locations around the footprint except for the cords.

Cut a board a few inches larger than the footprint of your machine and placed it over the hole you just cut. Drill four holes large enough for through the board and the table at each corner. large enough to fit the large bolts I bought to create a drop floor for the machine to rest on.

Dig around the drilled holes to drop the bolts flush on the table.

Cut up old self-healing cutting mats to fit around the machine, using sharp utility scissors or some other instrument to cut through the mats.

Carefully glue in place using Gorilla Glue (or similar) to bond the mats to the tabletop surface. Place books or other heavy objects on the surface for 24 hours until the glue sets.

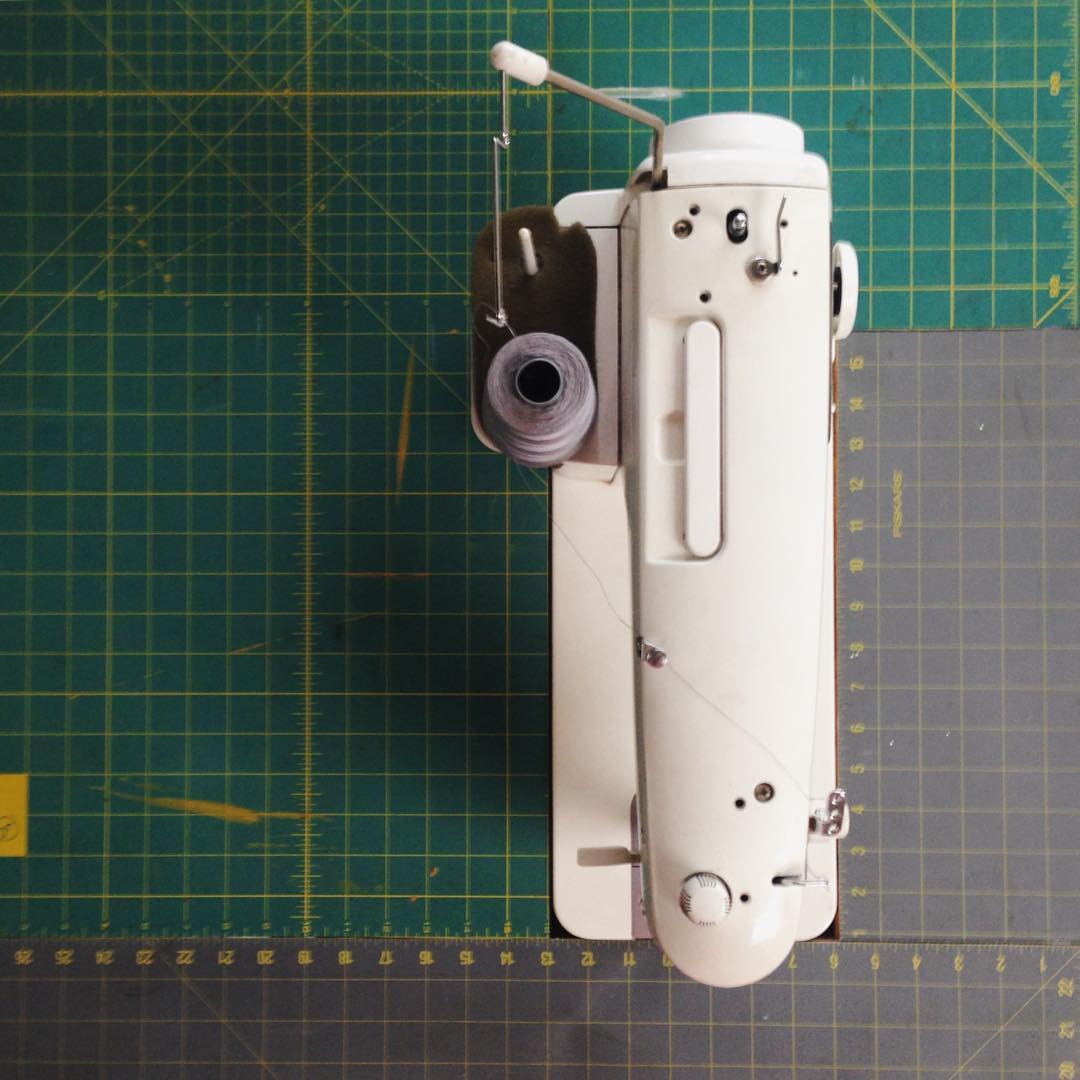

birdseye-view-of-inset-sewing-machine-table-lined-with-pieced-together-old-cutting-mats-makingdo-sewingtools-diy_24625020051_o

I love having the cutting mat surrounding my machine, since I'm often cutting my patchwork as I sew. Having the glued down cutting mats removes the hassle of the mat sliding around as I go back and forth from cutting to patching.

However I do not use my Juki for machine quilting so I can not attest to the smoothness of the surface for machine quilting. You may prefer to have the inset machine table without the cutting mat lining.

Remember these are general DO-IT-YOURSELF guidelines, that could and should be adapted to fit your particular machine and needs!